Tata chemicals has a plant site of 127 acres in dholera gujarat that can house manufacturing of active materials li ion cells and batteries of up to 10 gw per annum as well as the recycling operations.

Li ion cell manufacturing process.

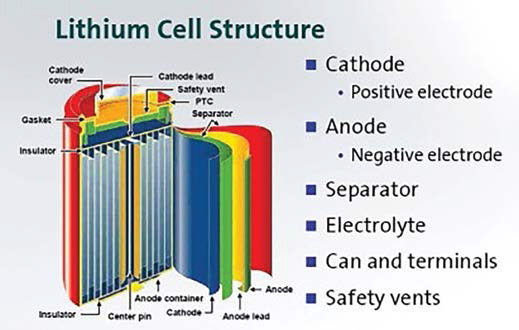

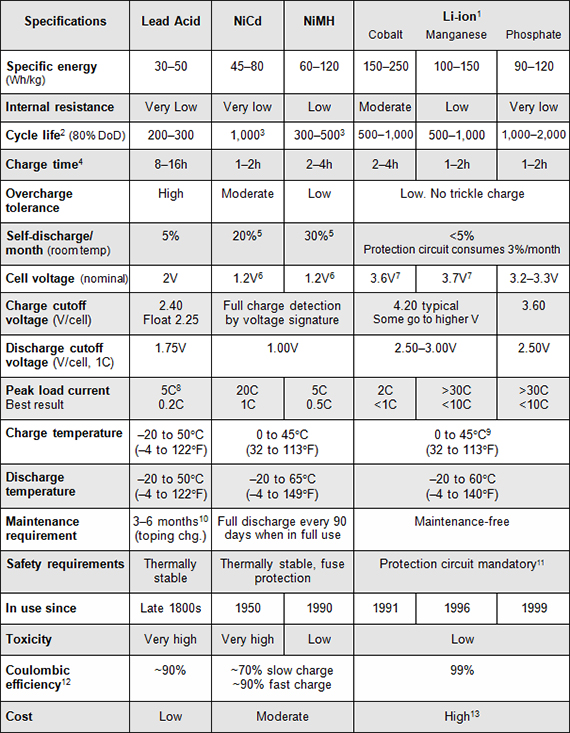

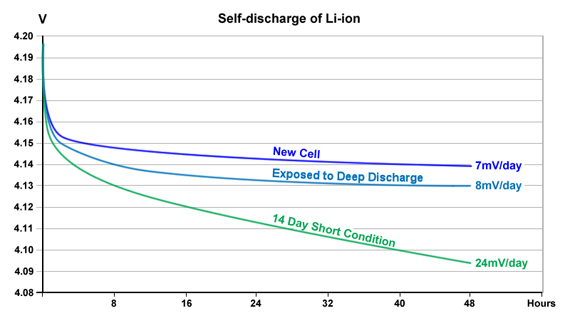

The processes used for manufacturing lithium batteries are very similar to those used in the production of nickel cadmium cells and nickel metal hydride cells with some key differences associated with the higher reactivity of the chemicals used in the lithium cells.

Pouch cell manufacturing process lithium ion pouch cell manufacturing guide.

Both the basic process chain and details of.

In the process of commissioning a commercial pilot cell manufacturing by 2021 which based on market demand could expand to 3 to 5 gw by 2025.

Use milling machine to mill materials into smaller sized particles.

Use furnace to sinter raw cathode active material and anode active material.

Enjoy the videos and music you love upload original content and share it all with friends family and the world on youtube.

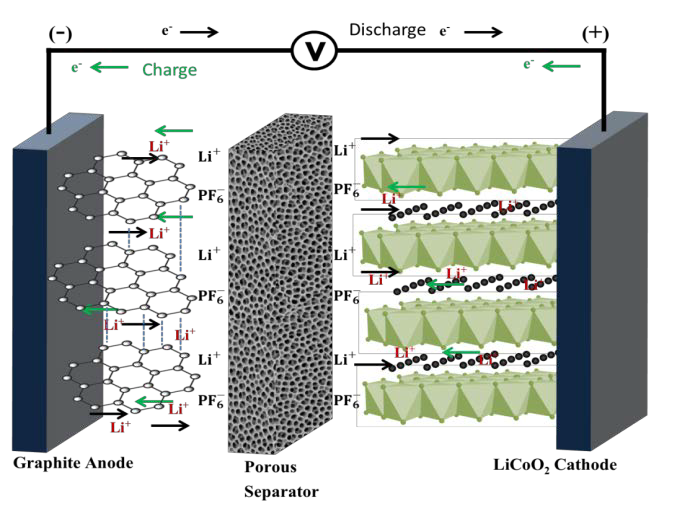

Lithium ion batteries have become the most important application of lithium and storage technology in the areas of portable and mobile applications e g.

The production of the lithium ion battery cell consists of three main process steps.

1 process cleanliness control in battery cell manufacturing a way to increase lithium ion battery quality yield safety during the production of li ion batteries numerous parameters are responsible for the.

The first brochure on the topic production process of a lithium ion battery cell is dedicated to the production process of the lithium ion cell.

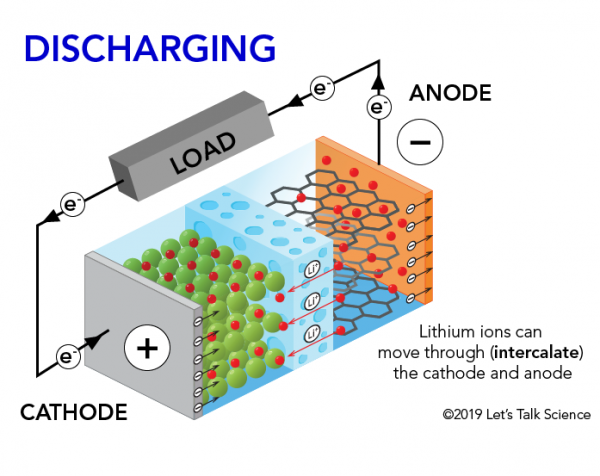

Lithium ion li ion batteries are rechargeable batteries with high.

Process of manufacturing pouch cell.

Laptops cell phones smartphones tablets power tools medical devices electric bicycles and electric cars.

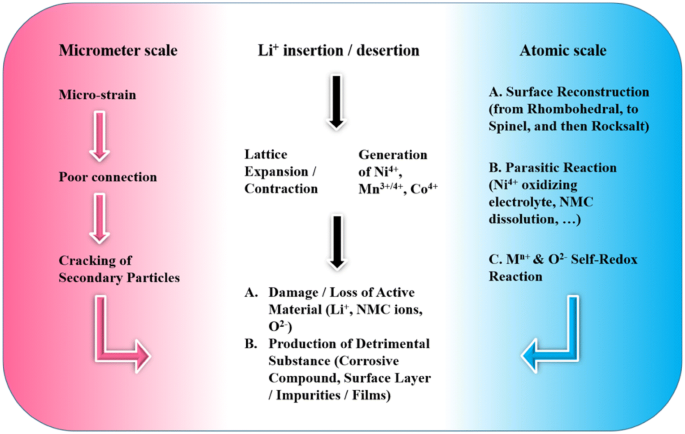

Lithium ion batteries and their manufacturing challenges.

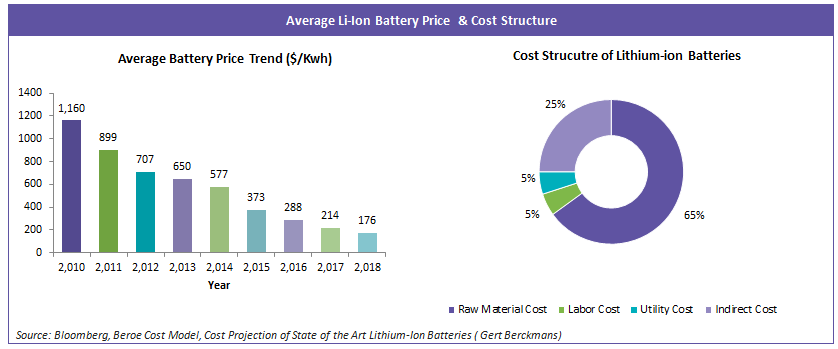

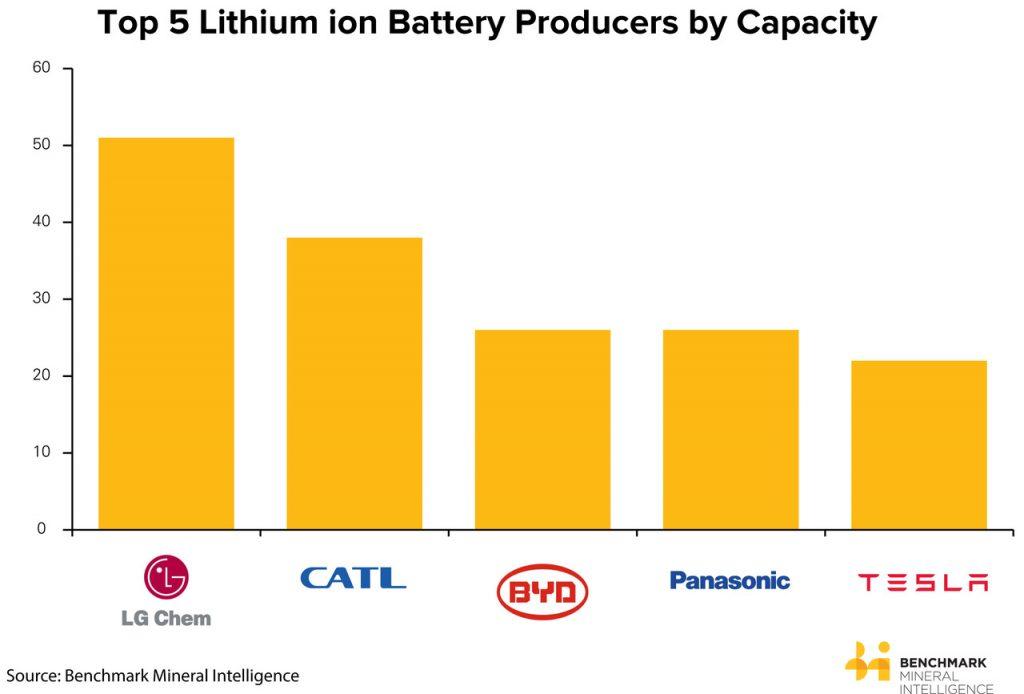

Regional competitiveness in automotive lib cell production this study models cell manufacturing cost and minimum sustainable price and examines development of lib supply chains and current lib market conditions.

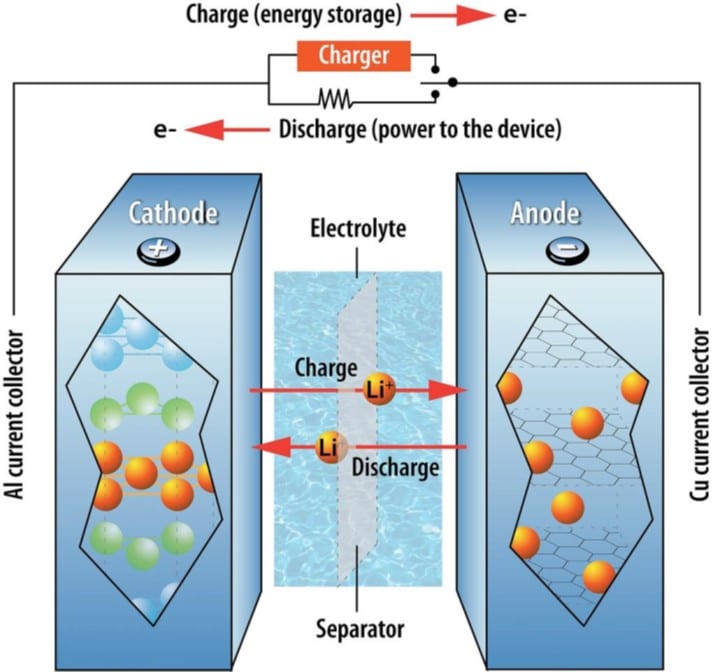

Lithium ion batteries are manufactured in sets of electrodes and then assembled in cells active material is mixed with polymer binders conductive additives and solvents to form a slurry that is then coated on a current collector foil and dried to remove the solvent and create a porous electrode coating.

Electrode production and cell finishing are largely independent of the cell type while within cell assembly a distinction must be made between pouch cells cylindrical cells and prismatic cells.

.jpg)